Laser scanning Exhaust Gas Cleaning System EGCS

Our extensive experience in the marine industry offers quality and cost-effective 3D laser scanning solutions for vessels that require Scrubber installation. The digital study produces a detailed 3D visualization of all areas of interest, providing accurate 3D models that facilitate the design and installation of the EGCS (Exhaust Gas Cleaning System).

Laser-scanning 3D modeling and building information modeling (BIM) have made most daunting tasks easier by providing a detailed digital plan of a vessel, increasing productivity during navigation, facilitating modernization and improving maintenance.

Exhaust Gas Cleaning System Scrubbing retrofits with single engines or multistreaming operations. Scrubbers are used to wash Sulphur Oxides (SOx) and other harmful compounds out from the exhaust gases.

Time is money, especially in the shipping and maritime industries. Enhancing productivity while repairing and retrofitting large vessels is crucial as stopping commercial operations is a total financial loss for ship-owners. To minimise time spent in the dock our company specialised in 3D modelling and measurements can survey in order to help architects to check for production clashes and to plan retrofit of a scrubber system.

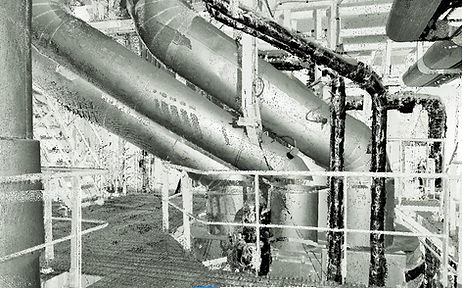

Scrubber systems are a diverse group of air pollution control devices. The scrubber system surveyed by NautiSCAN3D consisted of a steel tower on the ship funnel where sea water is injected to clean exhaust gas from Sulphur Oxides (SOx) and nitrogen oxides (NOx).

_JPG.jpg)

This system helps shipping companies to be compliant with the International Convention for the Prevention of Pollution from Ships (MARPOL) established by the International Maritime Organisation (IMO).

Emissions from vessels that involve Sulphur compounds is regulated. As per the rule, IMO has regulated the maximum allowable Sulphur content in marine fuels. Using low Sulphur content fuel is one option to comply with then requirements of MARPOL. Another alternative, which emerged as an economical option is to fix an exhaust gas scrubber. This allows the ship owner to use higher Sulphur content fuels, with the scrubber filtering out the rest of the Sulphur Oxides (SOX) thereby the emissions to atmosphere are kept within the limits allowed (from the 1st of January 2020, the limit for sulphur in fuel oil used on board ships will be reduced to 0.50% m/m).

Exhaust Gas Cleaning System Scrubbing retrofits with single engines or multistreaming operations. Scrubbers are used to wash Sulphur Oxides (SOx) and other harmful compounds out from the exhaust gases.

Time is money, especially in the shipping and maritime industries. Enhancing productivity while repairing and retrofitting large vessels is crucial as stopping commercial operations is a total financial loss for ship-owners. To minimise time spent in the dock our company specialised in 3D modelling and measurements can survey in order to help architects to check for production clashes and to plan retrofit of a scrubber system.

Scrubber systems are a diverse group of air pollution control devices. The scrubber system surveyed by NautiSCAN3D consisted of a steel tower on the ship funnel where sea water is injected to clean exhaust gas from Sulphur Oxides (SOx) and nitrogen oxides (NOx).

Our company collaborates with naval companies and field specialists and offers high quality services for shipping companies in all European ports (Portugal, France, Italy, Spain, Malta, Netherlands, Germany, Belgium, Turkey, ...), Spanish ports (Valencia, Algeciras, Barcelona, Las Palmas, Bilbao, Santander, Tarragona, El Ferrol, Cartagena, Avilés ...) and North Africa.